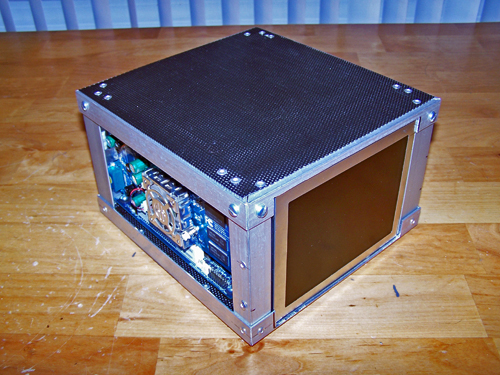

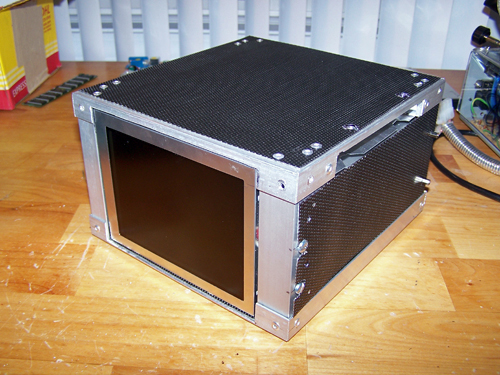

I put the whole thing

together, in the following picture you can see the flat head screws I used

to hold the top on... they work, but I freaking hate them. I've decided that

after I fire up the system and know for sure that it works I'll be riveting

the top down, if I ever have to remove it then I'll simply drill out those rivets,

whatever. Hardware

goes in, hardware comes out... time to completely disassemble this thing and

remedy stuff n' what's been bugging me.

One of the things bothering me was that

as it were the hard drive would

require the drilling of rivets to replace or remove it... in the picture below you can see

how I fixed that. I also cut and filed the Alum Angle to better fit the adapter

for the S-video, nibbled out the bottom side Alum Angle to better

fit the 6" LCD and also smartly changed out the four side rivets that mount

the LCD to the case for the above mentioned (now somewhat less hated) screws.

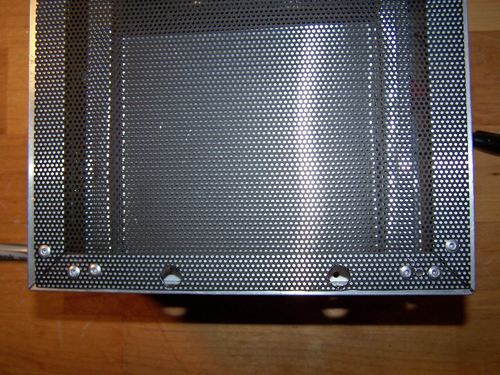

I cut up some more MeshX for

the sides and back of the case, the mesh is just mock fit for now and will be

among the very last things to be installed. I am using the mesh for

cooling (30%) and also for effect (70%), so when I'm done it should be (100%)

cool.

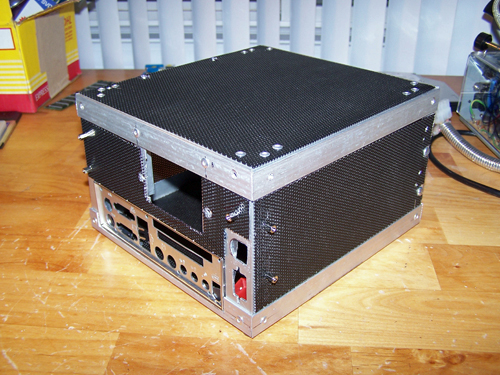

Below shows the CD and LCD

sides of the mod, the mesh panel on the CD side is there purely for looks and

will be a big part of the only lighting feature within the mod... more on that

later. Time to remove the LCD and do some more touch up drilling,

nibbling and filing to the case, not long now and I'll be able to start on the

outside section.

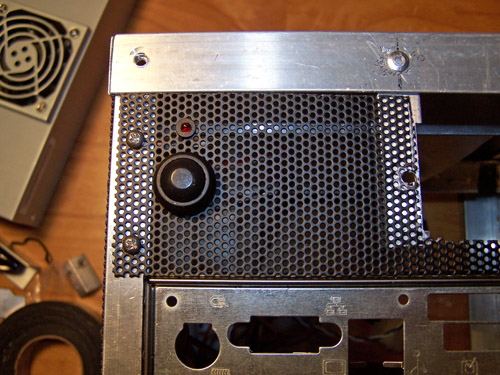

OK, I drilled the hole for

the power button and HDD activity LED, you can't see it in the picture below

but I also nibbled out some mesh on the other side to fit the cable from the

LCD.

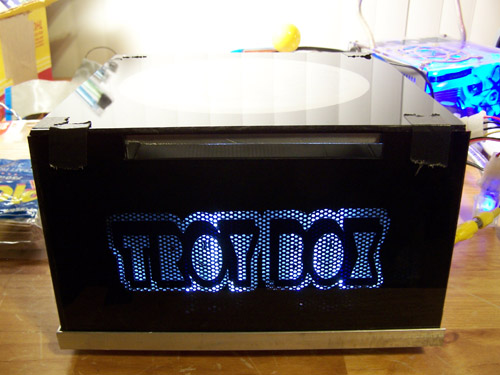

The following image is an

edited render of how I hope the final cut vinyl for the CD side will look, the

areas inside the letters will be masked off so the illuminated mesh can shine through.

Time to contact my vinyl guy and see

if he can help me out.

Below shows my lighting

idea, it looks way better live. I made the call and I should be able to

pick up my blue mirror chrome sticker by tomorrow and then I will begin

creating the acrylic outer sections.

10/30/08

Update...

I had a half used sheet of

AC Ryan Acryl panel kicking around that I covered on both sides with clear

contact paper, I measured my side markings onto it, scored it a few times

with a plasti-cutter knife and snapped it off.

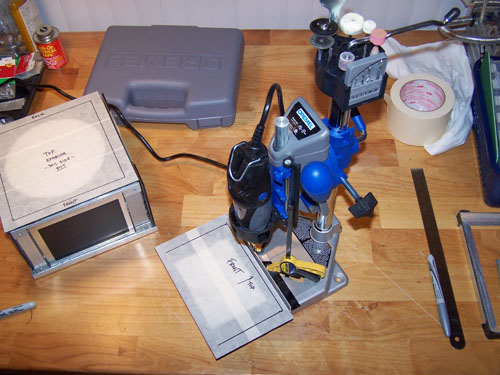

The plasti-cutter knife

works great for straight line cuts, but won't work for cutting the edge off the

piece of acrylic that's shown below. Enter the Dremel with a ripsaw

blade, I clamped a piece of Alum Angle to the acrylic as a guide for a nice

clean cut edge.

The following picture shows

all of the side acrylic pieces cut to size. I drilled an 80mm vent hole

in the video card side acrylic panel, the 'gluttony' mirror fan grills are

shown on top and my two freshly cut blue mirror chrome vinyl decals can be

seen to the left... not far now.

I masked off, measured and

cut the laser etched top acrylic panel and then duct taped the whole thing

together, mainly just to get a better look at where I'm at. I wanted to

do more today with it, but lost motivation to Guitar Hero and watching TV

instead... maybe I'll get more done on it tomorrow.

11/12/08

Update...

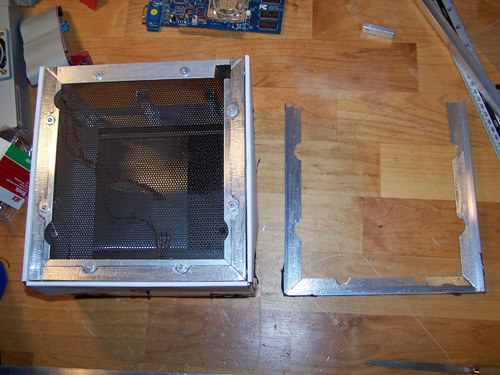

Below shows

the case bottom, next to it is the taped together bottom edging that will hold

the three acrylic side panels in place. I used a Dremel with a coarse

sanding drum to rough up the bottom edges of the case and also inside the

bottom edging, I then cleaned all the parts with some alcohol and a paper

towel.

Once everything was clean

and dry I whipped up some J-B Kwik and attached the bottom Alum Angle

edging. The J-B Kwik will need a few hours to fully cure so it's on to

some acrylic work.

The first thing I did was

cut the slot for the CD, I used my Dremel and ripsaw blade with a piece of

clamped alum angle for a guide, then finished tooling the slot with a Zona saw

and a pair of files. I also cut the mounting tabs off of the gluttony

fan grill, installed the TroyBoX vinyl and cut masks for my lettering, the

6" LCD and the top glutton etch.

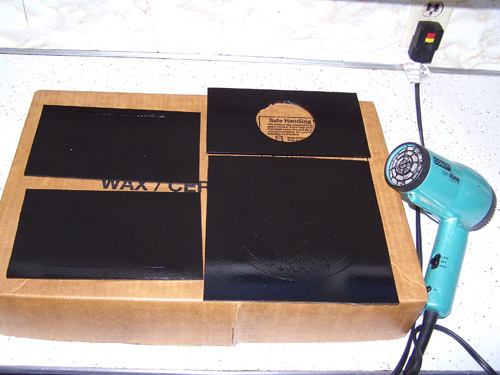

It's cold outside,

definitely not optimal spraying conditions but I know a work around - I call

it the in and out speed spraying technique and it only works when the wife

isn't home. Notice that all the pieces to be back painted are setting

inside a box...

The box is taken outside for

a quick spraying of Vinyl color and then comes back inside for some speed

drying, this is repeated as needed. It stinks to high hell and my wife

and kids hate it, to try and keep the stink down I use the inside of the box

for painting and the outside of the box for drying.

I removed the masking from

the panels and found that I had only hit for 50%, the top and blowhole side

panels came out great, but I'm calling mulligan and scrapping the LCD and 'TroyBoX'

side panels. I was almost going to show them here because they are still

useable, but I'll wait until all four sides are perfect instead.

11/16/08

Update...

Ok, all

four panels are finished and even though I still have to clean and polish them

they are now fit to be shown. Below is the video card side opening with

the mirrored Glutton grill over mesh accent.

Here is one of the finished

re-do panels, I hooked up a handheld video game to the 6" LCD to check

how well it lines up and it's spot on, I guess second times the charm.

The next picture shows the

other reworked side panel, it came out way nicer than the one it replaced and

even better than I expected.

Last but not least, the back

painted Glutton etched top panel... not far now.

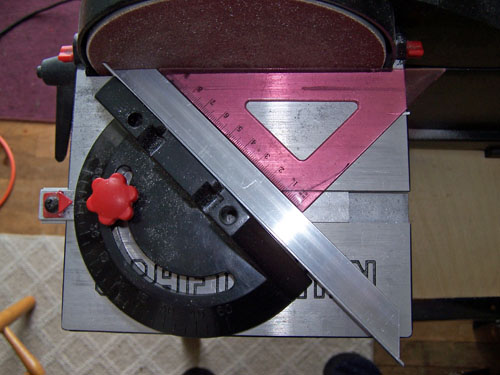

12/07/08

Update...

I cut all

the external Alum-Angle pieces using a hand saw and miter box (mainly just to

see how it would go), as expected the adjoining edges are rough and ill

fitting... even after filing they still need some serious help. Since

they are still salvageable I'll get my table sander out of the tool shed and set about making things right.

01/02/09

Update...

I'm

uncertain as to how much cat I can let out of the bag, but a big name magazine

wants to feature my work... the "TroyBoX" project now has a January

12 deadline - time to put the pedal to the metal. Below is a shot of the disc

sander and one of the Alum Angle top edges, the sander made short work of

truing up the edges and everything fits great now.

The TroyBoX

side panel had a problem with the light bleeding through where it was

brightest - mostly down low near the LED's. I busted out some red mirror

chrome vinyl and fixed it, no light will be seeping through now.

I masked off all of my

panels and loose fit all of the Alum Angle pieces together, I then traced

the edges onto the masking tape in marker.

I used a coarse sanding drum

on the Dremel and hit the inside edges of the Alum Angle, they got roughed up

pretty good.

I hope every good modder got a

Dremel Workstation for X-mas... below shows an acrylic panel that's fixing to

get a bunch of holes drilled in it using my 2nd favorite gift this year (1st

fave - wii GHWT), all of the panels will be drilled along their edges in

preparation for JB Weld.